Pulsarlube MS&MSP

De Pulsarlube MS & MSP units zorgen voor automatische smering van machines die onregelmatig worden gebruikt. Dit doen ze door synchroon te werken met de apparatuur, zodat oversmering wordt voorkomen.

Ontdek meer over de Pulsarlube MS&MSP

Product bestellen

Synchronized

Dispenses a preset amount of lubricant only when equipment is in operation.

LCD

Easy to program with built-in LCD and simple button controls.

60bar

Up to 8 lube points for multi-point / Max. 10m (33ft) for single point.

Service Pack

Substantial savings from the use of replaceable grease pouches and battery packs.

Pulsarlube MS&MSP Series 60, 125, 250, 500

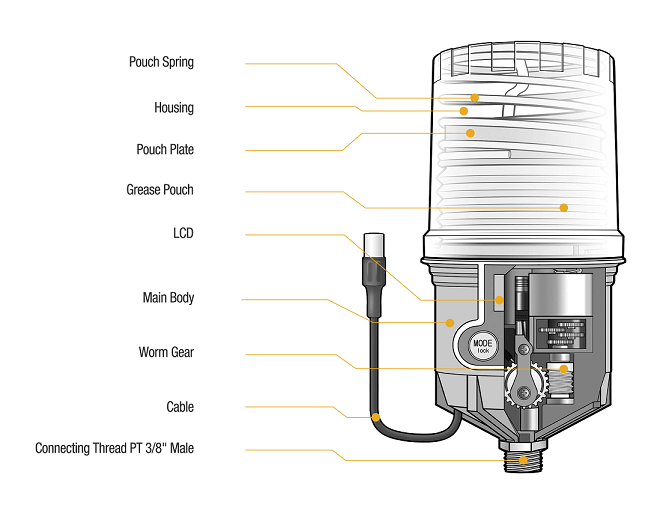

De automatische elektromechanische vetsmeerunit Pulsarlube MS is ontworpen om synchroon te werken met de apparatuur waarop deze is geïnstalleerd. Zolang de apparatuur in werking is, zal de Pulsarlube MS de vooraf ingestelde hoeveelheid smeermiddel afgeven, zodat verlies of verspilling van smeermiddel kan worden voorkomen. Als de apparatuur niet in werking is, gaat de Pulsarlube MS in de ‘standby-modus’ en wordt er geen smeermiddel afgegeven totdat de machine weer in werking treedt.

De automatische elektromechanische vetsmeerunit Pulsarlube MSP is ontworpen om synchroon te werken met de apparatuur waarop deze is geïnstalleerd. Zolang de apparatuur in werking is, zal de Pulsarlube MSP de vooraf ingestelde hoeveelheid smeermiddel afgeven, zodat verlies of verspilling van smeermiddel kan worden voorkomen. In tegenstelling tot de Pulsarlube MS is dit product een machinaal gesynchroniseerde, extern aangedreven unit die gevoed wordt door een op de machine aangesloten voeding of PLC. Het batterijpakket in de unit hoeft pas na circa 5 jaar te worden vervangen. De vetvulling moet echter worden vervangen na voltooiing van elke smeercyclusset.

Product dimensies

- MS&MSP60: Ø91mm(3.60″) x 181mm(7.13″) (H)

- M125: Ø91mm(3.60″) x 181mm(7.13″) (H)

- M250: Ø91mm(3.60″) x 210mm(8.27″) (H)

- M500: Ø92mm(3.62″) x 260mm(10.23″) (H)

![]()

Technische specificaties

| Specificatie | Waarde |

|---|---|

| Grease Pouch Capacity | 60ml/125ml/250ml/500ml (replaceable) |

| Power Supply | MS : DC 4.5V Battery Pack MSP : External Power Supply |

| Operating Pressure | 30~60bar (435~870psi) |

| Operating Temperature | Standard Alkaline Battery : -15˚C~60˚C (5˚F~140˚F)Optional Lithium Battery : -40˚C~60˚C (-40˚F~140˚F) |

| Dispensing Periods | 60ml : 1~12 month 125ml/250ml : 1, 2, 3, 6, 12 month & H (15 days) 500ml : 1, 2, 4, 6, 12, 18, 24 month & H (15 days) |

| Remote Installation | Max. 10m (33ft) with O.D. Ø6 tube |

| Multi-Point Installation | Max. 6m (20ft) with O.D. Ø6 tube (Up to 8 lube points) |

| Packaging | 10 Units/Case |

| Dispensing Periods (60ml) | 1,2,3…10,11,12 month |

| Dispensing Periods (125ml/250ml) | 1, 2, 3, 6, 12 month & H (15 days) |

| Dispensing Periods (500ml) | 1, 2, 4, 6, 12, 18, 24 month & H (15 days) |

![]()

Productcertificaten

| Certificaat | Waarde |

|---|---|

| N/A | N/A |

![]()

MSP Relay / MSP Power Supply Specification

| Product | Value | Voltage Rate Input Range | Voltage Rate Output Range | Power ON Indicator | Relay Box Dimensions | Wire Length |

|---|---|---|---|---|---|---|

| MS | Relay | AC100-480V, 0.5W/50~60Hz | Signal (Open collector type) | Red LED | 85mm (D) x 49mm (W) x 32mm (H) | Input 1m (3ft) / Output 4m (13ft) |

| MSP | VAC | AC Adaptor (100~220V) | 5.0V, 2A | Red LED | 85mm (D) x 49mm (W) x 32mm (H) | Input 1m (3ft) / Output 4m (13ft) |

| MSP | VDC | DC-DC Convertor (12~24V) | 5.0V, 2A | Red LED | 85mm (D) x 49mm (W) x 32mm (H) | Input 1m (3ft) / Output 4m (13ft) |

Snel downloaden

Handleiding MS&MSP in het Engels

Handleiding MSPOL in het Engels

Accesoires

Reducer, 3/8Part No.: A001

Reducer, 3/8Part No.: A002-S

Reducer, 3/8Part No.: A002

Socket, 1/4Part No.: A011

Socket, 1/8"F x 1/8"F Adaptor (Brass)Part No.: A012

90° Elbow, 1/4"F x 1/4"F Adaptor (Brass)Part No.: A019

90° Elbow, 1/8"F x 1/8"F Adaptor (Brass)Part No.: A020

90° Elbow, 1/4"M x 1/4"F Adaptor (Brass)Part No.: A021

90° Elbow, 1/8"M x 1/8"F Adaptor (Brass)Part No.: A022

45° Elbow, 1/4"M x 1/4"F Adaptor (Brass)Part No.: A023

45° Elbow, 1/8"M x 1/8"F Adaptor (Brass)Part No.: A024

Pipe, 1/8"M x 1/8"M x 50mm for divider block (Steel)Part No.: A106

Pipe, 1/8"M x 1/8"M x 100mm for divider block (Steel)Part No.: A107

Pipe, 1/8"M x 1/8"M x 150mm for divider block (Steel)Part No.: A108

Pipe, 1/8"M x 1/8"M x 200mm for divider block (Steel)Part No.: A109

Pipe, 1/4"M x 1/4"M x 50mm for divider block (Steel)Part No.: A121

Pipe, 1/4"M x 1/4"M x 100mm for divider block (Steel)Part No.: A122

Pipe, 1/4"M x 1/4"M x 150mm for divider block (Steel)Part No.: A123

Pipe, 1/4"M x 1/4"M x 200mm for divider block (Steel)Part No.: A124

Distribution Tubing, O.D. 5/16" (8mm) Urethan Tubing, 3ft Pre-filled with (Grease Type)Part No.: A212-1

Tube Fitting, Push-In Type, PC8-PT1/8"MPart No.: A239

Mounting Bracket, "L" ShapePart No.: B002

Self Drilling Screw, #8 x 20Part No.: B051

WasherPart No.: B057

Thread Converter, PT1/8"F x NPT1/8"M (Brass)Part No.: A243

![]()

Toepassingen

Semiconductors & Machine Tool

- Web Scrubbers

- Air Handing Units

- Clean Rooms

- Cooling Towers

- SMD PLB Lines

- LCD Panels

- Loader Robots

Directe montage installatie

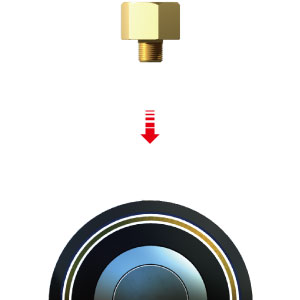

Reducer

| Type | Waarde |

|---|---|

| A001 | Reducer, 3/8″F X 1/4″M Adaptor (Brass) |

| A002 | Reducer, 3/8″F X 1/8″M Adaptor (Brass) |

| A003 | Reducer, 3/8″F x 1/8″M Adaptor (Steel) |

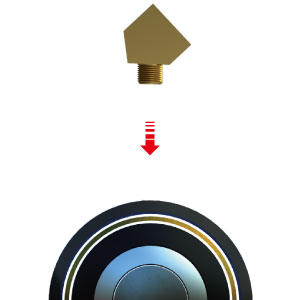

45˚ Elbow

| Type | Waarde |

|---|---|

| A023 | 45° Elbow, 1/4”M X 1/4”F Adaptor (Brass) |

| A024 | 45° Elbow, 1/8”M X 1/8”F Adaptor (Brass) |

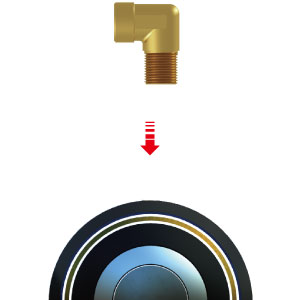

90˚ Elbow

| Type | Waarde |

|---|---|

| A019 | 90° Elbow, 1/4”F X 1/4”F Adaptor (Brass) |

| A020 | 90° Elbow, 1/8”F X 1/8”F Adaptor (Brass) |

| A021 | 90° Elbow, 1/4”M X 1/4”F Adaptor (Brass) |

| A022 | 90° Elbow, 1/8”M X1/8”F Adaptor (Brass) |

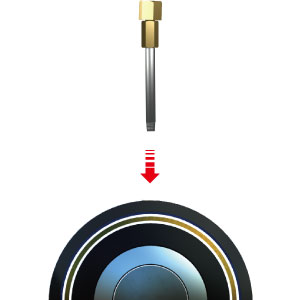

Socket + Pipe + Reducer

| Type | Waarde |

|---|---|

| A011 | Socket, 1/4″F x 1/4″F Adaptor (Brass) |

| A012 | Socket, 1/8″F x 1/8″F Adaptor (Brass) |

| A121 | Pipe,1/4”M X 1/4”M × 50mm (Steel) |

| A122 | Pipe,1/4”M X 1/4”M × 100mm (Steel) |

| A123 | Pipe,1/4”M X 1/4”M × 150mm (Steel) |

| A124 | Pipe,1/4”M X 1/4”M × 200mm (Steel) |

| A106 | Pipe, 1/8″M x 1/8″M x 50mm for divider block (Steel) |

| A107 | Pipe, 1/8″M x 1/8″M x 150mm for divider Pipe, 1/8″M x 1/8″M x 100mm for divider block (Steel) |

| A108 | Pipe, 1/8″M x 1/8″M x 150mm for divider block (Steel) |

| A109 | Pipe, 1/8″M x 1/8″M x 200mm for divider block (Steel) |

Single point remote installation

Kit No. 2000RC-1

| Type | Waarde |

|---|---|

| A005 | Reducer, 1/4″F x 1/8″ M Adaptor (Brass) |

| B002 | Mounting Bracket, “L”Shape |

| B051 | Self Drilling Screw, #8ⅹ20 |

| B057 | Washer |

| A012 | Socket, 1/8”F x 1/8”F Adaptor (Brass) |

| A239 | Tube Fitting, Push-In Type, PC8-PT1/8″M |

| A212-1 | Distribution Tubing, O.D. 5/16″(8mm). Urethan Tubing, 3ft Pre-filled with (Grease Type) |

| A243 | Thread Converter, PT1/8″F X NPT1/8″M (Brass) |

Note : For remote installation using a tube, use an 8mm O.D. (5/16″) tubing pre-filled with the same or compatible grease as the grease contained in the unit. Recommend using under short dispensing period settings due to powerful dispensing pressure.

Multi-Point installation

Electromechanical Products using a divider block ( up to 8 points )

Comments